Have you not done any kind of maintenance for a long period on your Singer Sewing Machine? Or, is your sewing machine making noise? Well, whatever the reason is, you are here to learn about lubricating a Singer sewing machine properly. I have explained the whole process of lubrication is simple steps so that a beginner may also learn without any issues.

In order to avoid the frustration of knowing how to properly oil a Singer sewing machine, I’ve put together an easy-to-follow guide that includes all steps necessary for successful completion. It also includes precautions you should take prior to starting this project as well as what the proper way is in terms of oiling your Singer sewing machine so it functions at its best for many more years!

Oil your Singer sewing machine to keep it running smoothly. Oil is a lubricant that helps prevent metal parts from rubbing against each other and generating heat, which can lead to damage to the fabric or thread being sewn. Tread lightly when oiling your Singer sewing machine.

It’s important to take caution in order to avoid getting oils on the floor or clothing, and also ensure that no excess oil is being applied in places it is not necessary. Excess oil will collect dirt and dust particles quickly, which can lead to a decrease in performance over time due to the increased buildup. It is recommended that you oil your Singer sewing machine once every six months or so in order to maintain an optimum level of lubrication and keep it functioning at its best for many years.

Things to consider before oiling a Singer Sewing Machine

You need to consider certain things to oil your Singer sewing machine properly otherwise you may not get the best results. You can follow these steps below to oil your Singer sewing machine at best.

Choose the best oil

Singer provides its own and official Singer Oil for its sewing machines which is reliable and prepared by looking at the material of their own sewing machine.

Different Singer sewing machines require different types of oil. A good rule to follow is that if you are using the machine daily, then it’s best to use lightweight oils (such as sewing machine motor oil). If you’re not using your Singer sewing machine very often, heavier and thicker oils will be a better option. Also, you need to make sure that you are using the recommended oil for your model or use the oil which comes with the accessories. You should not use oil from a bad brand because it can cause damage to your machine.

Cleaning parts before oiling (lubricating)

You should clean your parts before oiling a Singer Sewing Machine. This will make sure that you are not re-applying old, dirt, and dust particles which can cause problems for the performance of your machine over time. It’s important to use warm water only as it contains less abrasive materials than soap or other household cleaners.

If you use a degreaser, make sure to rinse well with warm water after rinsing and then dry thoroughly before applying oil or the machine may complain of an unpleasant odor if it is used for sewing soon thereafter. If using soap, be careful not to use too much – just enough to get all surfaces wet without soiling your fabric.

The right time to oil your Singer Sewing Machine

Apply oil to your Singer Sewing Machine on a dry day, preferably in the morning. The machine should not have been used for sewing or quilting recently and it is best if you know that there are no plans for using it anytime soon after applying the oil as excess heat will cause fresh oils to break down quicker than usual. If you plan to oil your machine on a warm, humid day then you should allow it to air dry before using.

And, it depends on your machine model after how much time you should oil your sewing machine. Some sewing machines do not require regular maintenance while some do require proper oiling and maintenance for their smooth functioning.

Choose the best oiling utensil

It is advised to use cotton or a lint-free cloth for your Singer sewing machine. The cloth should be small enough so that you can easily wipe the area of application. It’s also helpful to have an old toothbrush on hand in case any dirt has accumulated around the needle plate and feed dog area. This will help you to get into those tight corners and loosen up any dirt that may be clogging the oiling hole on the machine.

When you are cleaning out your Singer sewing machine, it is important to be thorough and make sure that there isn’t any dirt or hair blocking the oiling hole on your machine. You can use an old toothbrush in order to scrub around the feed dog area of your device.

This will help loosen anything that may have accumulated there and give you a clear view of the oiling hole. It’s important to remember that although Singer sewing machines are not made with excessive complications, they still need some expert care in order to keep them running smoothly for years to come.

It is advised that all owners should check their machine regularly so as not to miss any dirt or hair clogging the oiling hole.

Know the parts properly

Different models have different areas which require more or less attention during an oiling session. Some of these locations include needle plate, feed dogs, shuttle hook, bobbin compartment (if applicable), and the lower thread path, etc.

You should not lubricate that part of a Singer sewing machine that does not require it, as this can do more harm than good. If you choose to lubricate the feed dogs, it is best if you use a high-quality sewing machine oil such as Singer’s own brand of Oiler.

A tiny drop should be sufficient for each dog and needle plate hole. This will ensure that your stitch length remains consistent without any slipping or skipping stitches.

The needle plate is another area of your sewing machine which should be lubricated. Oil the holes on the front and back, one hole at a time with Singer’s own oil (or any other high-quality oil). This will ensure that there are no problems with tension in these areas. If you have been using low-quality oils or aerosol lubricants, this is the perfect opportunity to switch over and use Singer’s own oil.

When it comes to lubricating shuttle hooks or bobbin compartments for machines with a bobbin compartment (i.e., most models) you should only do so if your machine requires regularly scheduled maintenance of these areas. If not, it is best to leave them alone.

If you choose to lubricate the shuttle hook, it is better if you use high-quality oil and perform this task outside of the machine as opposed to inside where there are little nooks that can trap an excess amount of thread or sewing debris. It would also be wise not to overfill any of these areas or to over-lubricate any of the machine’s working parts.

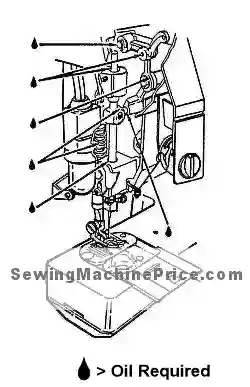

Moreover here below is the image with the signs of the drop pointing toward the internal parts which require oiling in a Singer Sewing Machine.

Protect yourself from the oil

Wear an old shirt that you don’t mind ruining to protect your clothes and cover your arms with an old towel. Be sure to work in a well-ventilated area because sometimes the oil is very smelly! Use caution when pouring any fluid into your machine while it’s running as you can cause problems with the internal workings of the machine.

Put on rubber gloves to protect your hands from getting oil all over them and then get out the metal container of sewing machine oil, put in a few drops onto a paper towel or cloth, and wipe any excess grease off of the side panels near where you would need to pour it into the reservoir.

Apply the correct amount

It’s important to understand that oiling a Singer sewing machine isn’t just applying some of the lubricants and then moving on. If you don’t apply enough, parts won’t be fully covered in oils (which can lead to damage as described above). On the other hand, if you put too much oil into your Singer sewing machine it can cause an unnecessary mess.

Each sewing machine is different, so you’ll need to experiment a little to find the right amount for your particular model. You may also want to apply oil more often if it’s been a while since your last application or if you’re doing some heavy work on the machine (sewing thick fabrics). Applying too much oil can cause an unnecessary mess and too little will not fully cover parts in oil.

Proper Way to Oil a Singer Sewing Machine

There are many mistakes people make when oiling a sewing machine. Some of them include using the wrong type of oil, applying too much or not enough, and forgetting about certain parts like spool pin, tension, free arm, and bobbin case.

If you are going to oil your machine make sure that you do the following steps.

- Turn off the power switch on the rear panel before moving forward

- Check all parts of your machine for signs of wear or damage before applying any type of oil.

- Clean the metal parts of the machine with a clean cloth before applying any type of oil

- Apply a small amount (one drop) on each spool pin shaft and then work it into the thread spool pin before adding more oil.

- Work a small amount of oil around the tension knob with your finger, making sure that you get all areas including the top and bottom while rotating it to work in as much oil as possible.

- Apply a tiny drop (one teaspoon) to each sewing machine needle plate slot and then work it in by gently sliding the needle plate back and forth.

- Apply a small amount (one drop) on each hook at the top of your machine’s bobbin case, working it in with your fingers until all surfaces are covered evenly.

- Apply a small amount to the inside stitching area where needles come up from underneath the sewing surface: this is the area that will do the most work and it should be lubricated.

- Apply a small amount to each surface where metal meets metal: top of the free arm (it rotates), feed dog, thread tension discs, side plate screws, needle threader slot, etc.

- Oil all surfaces on the machine using one drop at a time and then work it in before adding more.

- Apply oil to any other metal surface that touches another piece of metal (e.g., needle plate screws, side plates).

- Allow the machine to run for a few minutes with the handwheel turned so that all surfaces are covered evenly by oil and can be properly lubricated.

- Clean the machine with a damp cloth or vacuum cleaner after oiling.

The good and bad of oiling (lubricating) your Singer sewing machine

Good

- The process is easy to do at home. It prolongs the life of your sewing machine. You get a better stitch quality when it’s done right.

- A well-oiled machine is easier to thread.

- The oil prevents the friction between metal parts that can cause excessive wear and eventual breakdown of your sewing machines.

- When you don’t oil a Singer sewing machine, it can lead to damage in other areas such as the belt or motor which could be very costly to repair.

Bad

- The process is time-consuming.

- It takes a long time for the oil to penetrate and soak into all parts of your sewing machine, so you will not see any immediate results after applying.

- If it’s done wrong, there are consequences such as making everything greasy or too much lubrication which can cause a buildup of oil on the machine.

Tutorials on Oiling (lubricating) Singer Sewing Machines

FAQ about oiling (lubricating) a Singer Sewing Machine

Does oiling a Singer Sewing Machine increase its efficiency and life?

Yes, oiling a sewing machine may increase your sewing machine efficiency and also the life cycle itself. A well-oiled sewing machine can last much longer than one that hasn’t been oiled properly. It can also provide more power and make the stitches of your handiwork stand out more clearly. The thing to keep in mind is that the oil used must be special; not just any old motor oil will do the trick because it will get clogged up the minute you start using it on a sewing machine.

How to oil a Singer 5050C Sewing Machine?

The Singer 5050C Sewing Machine is a great choice for beginner sewers as it is easy to operate. But if you want to keep your machine running at its best, then it’s important to oil it regularly. Just like with any other sewing machine, there are specific steps that need to be followed in order to oil your 5050C machine correctly. Be sure that you have the following supplies: Lubricant (Singer Oil®), a Cone wrench, a Soft cloth or paper towel and/or brush, a Clean old shirt, and Rubber latex gloves. Singer 5050C is like other normal Singer Sewing Machines and its front arm cover can easily be opened with a screwdriver. Just open that front arm cover and reveal its internal parts where oiling is required as you can see the required oiling parts of a Singer Sewing Machine in the image that I shared above.

How to oil a Singer 4411, 4452, 4432 Sewing Machines?

Well, Singer 4411, 4452, and 4432 are a part of the Singer Heavy Duty Sewing Machines series. These are a bit old model and are not computerized so all of these require proper oiling after some time. The most important part of the oil in Singer 4411, 4452, or 4432 is their bobbin area. You can simply unveil the bobbin area by removing the sewing needle plate. Just add some Singer Oil drop there and then follow the same process as described above, oiling the internal parts by removing the front arm cover.

How to oil a Singer Treadle Sewing Machine?

It is not hard to lubricate your Singer treadle sewing machine. There will be some holes over the sewing machine’s body and arm. These arms are kept by the manufacturer especially for oiling the specific parts under these holes. So, find all those holes and you need to put one drop at each hole. If you are feeling load while operating your Singer treadle sewing machine then you might need to properly check and oil the treadle part of your Singer sewing machine.

Conclusion

After all, is said and done, you will have a wonderfully oil-free, smooth-running machine. If you follow the instructions step-by-step, you’ll be in good shape and all that remains is an enjoyable sewing experience.

Hopefully, this guide has helped you learn more about Singer sewing machines and how to properly oil your machine. It’s an important part of keeping your machine humming along at its maximum potential. If it has been a while since you last oiled your machine, we recommend getting it back up and running as soon as possible after reading this article so that it continues to perform daily tasks without difficulty or hassle. If you have any questions, please let me know.